A Lockmaker

in Marion

Don Cuthbert, supervisor, commercial-industrial sales in Marion, poses left with Dick Tway of

Wilson Bohannan. Pictured above is a cutaway lock, showing the springs and pins which

control whether or not a particular key will work the lock.

"A Western utility put several locks through a severe salt immersion test. When they took them out, ours had held up best --- so they bought their locks from us" The speaker is William D. Tway of Wilson Bohannan, a lock manufacturer of Marion, Ohio.

The kind of quality built into locks from Wilson Bohannan has been a tradition since the business was established in 1860---by the founder Wilson Bohannan. Much later the firm moved to Marion and began operations there in 1927.

At one time they built switch locks for the interurban lines which were, in many cases, the predecessors of the public utilities of today. Many of their customers are public utilities and have been buying locks from them for 40 or 50 years.

It's very possible that most people have never heard of Wilson Bohannan. They deal with a very specialized clientele---and they only make and sell locks.

A majority of the locks produced are all-brass construction. "Brass doesn't rust" a representative says. "As long as the locks are maintained with graphite, they'll work" The locks are used on meters, transformer pad mounts and substation gates, often standing in the weather for years at a time. A period of ten years isn't an unreasonable test period.

Don Cuthber examines the lock bodies

which are machined at extremely close tolerances from

a single piece of brass.

The plant in which the production of the locks takes place isn't large. but it is clean, carefully laid out and well lighted. A glance at the arrangement of the rollered conveyors shows the steps in a lock's assembly.

Bodies of the locks are a single piece of brass. To them are added the shackle and the key barrel, with its pins and springs. matching the shape of the key the lock will take. After the lock works as it should, the body of the lock receives a finishing polish, and is ready to secure a piece of equipment.

There are two main types of lock

systems. Locks can have a master key or be keyed alike. In the case

of a master key there may be a number of locks, each of which opens with

an individual key, and all of which can be opened with a master key.

More common are the locks which all take the same key. Since the

locks are used in many different locations --- for instance, on substation

gates --- it's simpler to have all the locks keyed alike.

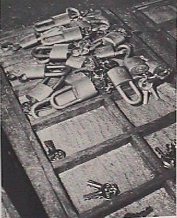

Locks, already fitted with their keys

await a final polish and shipment.

What Wilson Bohannan sell to its many utility customers is an extremely strong and durable lock, one that, with a little graphite to keep the parts working smoothly, will last a long, long, time.

Materials and accuracy are the most important items in the manufacture of the locks. How accurate? The barrel of the lock and the hole is which it fits are machined to extremely close tolerances. Standards for the employees at Wilson Bohannan are also exacting.

They've been in business a long time ---more than a century. There is a family tradition of quality workmanship behind every lock coming from the WB plant in Marion. And many of their customers have been customers for a long time. Wilson Bohannan will very likely keep those customers. *

***Article is from The Ohio Edisonian --- February 1973